Industrial Paints

These are the industrial paints we stock.

If you don't see what you are looking for, please contact us, and we will see how we can help!

AMERCOAT

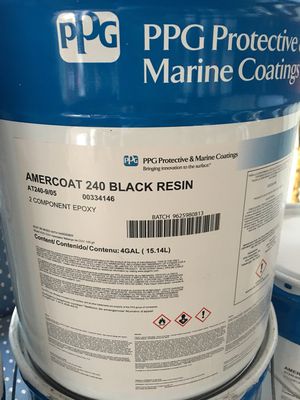

| Amercoat 240 Corrosion Resistant PrimersAmercoat 240 is an edge retentive, surface tolerant, corrosion resistant, two component, high-solids epoxy primer. Amercoat 240 is designed to reduce edge corrosion on surfaces with angles and welds where primers usually provide the lease amount of protection. Amercoat 240 is insulative and protects against corrosion by forming a barrier to water and salts. Amercoat 240 can be thinned Amercoat 65 thinner. |

| Amercoat 385 Corrosion Resistant PrimersAmercoat 385 is a surface tolerant, corrosion resistant, polyamide epoxy primer that is insulative and protects substrates by forming a barrier to water and salts. Amercoat 385 can be thinned with Amercoat 65 or Amercoat 911 in applications that allow 340 grams per liter or greater VOC. |

| Amercoat 385LH Corrosion Resistant PrimersAmercoat 385LH is a low HAPs (Hazardous Air Pollutant) version of Amercoat 385 which meets California’s CARB standards for Metal Parts Shop Coating. |

| Amercoat 385PA Corrosion Resistant PrimersAmercoat 385PA is a zinc phosphate, corrosion resistant, polyamide epoxy shop primer that provides corrosion protection through a zinc phosphate inhibitive process as well as an insulative barrier type process. Amercoat 385 PA can be thinned with Amercoat 65 thinner or Amercoat 911 thinner in applications that allow 340 grams per liter VOC or greater. |

| Amercoat 65 Thinner Corrosion Resistant PrimersWe recommend you consider purchasing Amercoat 65 thinner which is blended to improve the application of Amercoat 68HS, Amercoat 240, Amercoat 385 and Amercoat 385PA in varying environmental conditions. |

| Amercoat 68HS Corrosion Resistant PrimersAmercoat 68HS is a corrosion resistant zinc rich epoxy primer that protects steel substrates by sacrificing the zinc component and also insulating the steel substrate through barrier properties. Amercoat 68HS is designed to meet the needs of steel structures in coastal, high-humidity and offshore environments. Amercoat 68HS can be topcoated with PSX 700, Amershield, Amershield VOC, Amerlock 400, Amerlock 2, Amercoat 240 and Amercoat 385. Amercoat 68HS is thinned with Amercoat 65 thinner or Amercoat 911 thinner. |

| Amercoat 68HS VOC Corrosion Resistant PrimersAmercoat 68HS VOC is a corrosion resistant zinc rich epoxy primer that protects steel substrates by sacrificing the zinc component and also insulating the steel substrate through barrier properties. Amercoat 68HS VOC is designed to meet the needs of steel structures in coastal, high-humidity and offshore environments and also meets California’s 100 grams per Liter VOC requirements for the SCAQMD. Amercoat 68HS VOC can be topcoated with PSX 700, Amershield, Amershield VOC, Amerlock 400, Amerlock 2, Amercoat 240 and Amercoat 385. Amercoat 68HS is thinned with Amercoat 65 thinner or Amercoat 911 thinner. |

| Amercoat 851 Flow ControlAmercoat 851 reduces the surface tension of polyurethanes. Amercoat 851 can be helpful when roller and brush applying polyurethanes. |

| Amercoat 866M AcceleratorAmershield and Amershield VOC can be accelerated with Amercoat 866M to enhance dry to touch and dry through times. Amercoat 866M and should be used judiciously with no more that 1.5 ounces per gallon. |

| Amercoat 911 ThinnerFor shop application, Amershield can be thinned with Amercoat 911 thinner for OEM customers that are meeting HAPS requirements. These customers usually thin no more than 15 ounces per gallon. |

| Amercoat 911 Thinner Corrosion Resistant PrimersAmercoat 911 thinner can also be used to thin Amercoat 68HS, Amercoat 240, Amercoat 385 and Amercoat 385PA in varying environmental conditions. Applicators requiring non-HAPS thinners in their production facilities use Amercoat 911 thinner. |

| Amercoat 923 ThinnerFor shop application, Amershield can be thinned with Amercoat 923 thinner with up to 15 ounces per gallon in most shops in California. |

| AMERCOAT® 450H Top CoatAmercoat 450H is a thin film acrylic polyurethane with a performance industrial gloss finish. Amercoat 450H meets SCAQMD Rule 1107 for shop application as packaged. |

| AMERCOAT® 450H Top CoatAmercoat 450H is a thin film acrylic polyurethane with a performance industrial gloss finish. Amercoat 450H meets SCAQMD Rule 1107 for shop application as packaged. |

| AMERCOAT® 450HSG Top CoatAmercoat 450HSG is a thin film acrylic polyurethane with a performance industrial semi-gloss finish. Amercoat 450HSG meets SCAQMD Rule 1107 for shop application as packaged. |

AMERSHIELD

| AMERSHIELD® Top CoatAmershield is a two component hybrid polyester/acrylic polyurethane offering excellent chemical resistance and flexibility as well as ultra-violet stability in an performance industrial finish coating. Amershield is compliant with California Air Resources Board regulations for shop application, but for field application, Amershield VOC should be used in California. |

| AMERSHIELD® VOC Top CoatAmershield VOC is a less than 100 grams per liter VOC, two component hybrid polyester/acrylic polyurethane offering excellent chemical resistance, ultra-violet resistance and flexibility in an performance industrial finish coating. Amershield VOC is both California Air Resources Board compliant and SCAQMD Rule 1113 compliant as packaged. |

NOVAGUARD

| NOVAGUARD™ 810 Tank LiningsNOVAGUARD 810 can be applied as a one coat tank lining system using heated airless spray plural component equipment. |

| NOVAGUARD™ 840 Tank LiningsNOVAGUARD 840 can be applied as a one or two coat system with a total dry-film thickness as low as 12 mils per coat. Apply Novaguard 840 by standard single feed airless spray, or by brush or roller for repair and stripe coating. |

PPG

| PPG 97-739 EPA Exempt ThinnerPPG 97-739 EPA exempt thinner is a premium thinner that will optimize flow characteristics of Amershield and Amershield VOC without adding regulated VOC content to the coating during application. PPG 97-739 is highly effective as a thinner and thus coatings may require less of this thinner than other recommended thinners. |

PSX

| PSX 700 Top CoatPSX 700 is a two component extended life-cycle polysiloxane-epoxy offering excellent ultra-violet resistance, abrasion resistance, erosion resistance, corrosion resistance and stain resistance. PSX 700 is less than 100 grams per liter VOC, contains no dangerous isocyanates and is low odor during application. PSX 700 is SCAQMD Rule 1113 compliant as packaged in solid colors. PSX 700 Brochure |

| PSX® ONEPSX ONE is a single component polysiloxane acrylic coating that provides excellent weathering, abrasion resistance and stain resistance in an easy to apply one part material. PSX ONE is low odor and contains no dangerous isocyanates. PSX ONE is California Air Resources Board compliant as packaged, but is NOT compliant with SCAQMD Rule 1113. |